VAD 5400A Asphalt Distributor

VAD Series Asphalt Distributors and Emulsion Sprayers by Vimpo, a comprehensive solution for precision asphalt distribution and emulsion spraying in road construction and maintenance. Engineered with cutting-edge technology, these versatile machines offer seamless functionality, delivering precise and uniform application of asphalt and emulsion materials. The VAD Series ensures optimal performance and efficiency, boasting advanced features that streamline the distribution process.

Equipped with user-friendly controls and precision systems, these distributors and sprayers guarantee accurate and controlled spraying, enhancing road surface durability and quality. Whether it’s asphalt distribution or emulsion spraying, Vimpo’s VAD Series sets the standard for excellence, providing unparalleled reliability and performance in road construction. Elevate your projects with the VAD Series and experience the epitome of precision and innovation in asphalt distribution and emulsion spraying technology.

VAD 5400A Proportional Asphalt Distributor

With the VAD5400 proportional control system, amount of material to be spread on to the surface which is pre-determined by the operator is fixed. With its specially designed Spray Bar, this amount is precisely spread at 5400mm width.

The control of the system is provided by the panel in the operator's cab. After the amount of material to be spread per m2 and the spread width has been selected, the start of the spreading, the speed of the pump according to the speed of the vehicle adjustment and the stop of the vehicle with automatic stopping of the spreading happen automatically.

Total spread material, km, instantaneous vehicle speed, instant pump speed can be seen by the operator on the screen of the panel.

VAD 5400A Asphalt Distributor Technicial Features

| Spray Width | Up To 5400mm Spray Width |

|---|

| Spray Groups | 300mm Spray Groups |

|---|

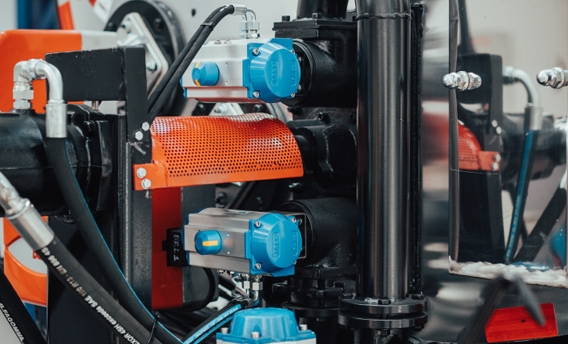

| Pump Type | VA Series Bitumen Pump |

|---|

| Bars | Foldable Extension Bars |

|---|

| Control | Digital Control |

|---|

| Spray Bar Movement | Hydraulicspray Bar Movement |

|---|

| Heating | Diesel Burner Heating |

|---|

| Control | Front And Rear Control Panel |

|---|

| Optional* | Thermal Oil Heated Spray Bar |

|---|

| Optional* | Thermal Oil Boiler |

|---|

| Optional* | External Diesel Engine |

|---|

| Optional* | Rear View Camera |

|---|

| Optional* | Automatic Proportional Spraying |

|---|

VAD 5400A Asphalt Distributor General Features

| Capacity | 8.000 - 13.500 Liters |

|---|

| Isolating Sheet | Aluminium Sheet 1mm |

|---|

| Isolating Material | Rockwool 50mm |

|---|

| Drive Type | Hydrostatic Control |

|---|

| Power | Vehicle PTU (Power Transmission Unit) |

|---|

| Controls | Digital Control |

|---|

| Pump Type | 3”VAD Pump (80m3/h) |

|---|

| Spray Bar Span | 2400 - 5400mm |

|---|

| Spreading Lane Width | 300mm, 18 Groups of Pneumatics |

|---|

| Valve Controls | Pneumatic - Electric On-Off |

|---|

| Heating System | Two Diesel Burners(min 190kw, max 310kw) |

|---|

VAD 5400A Bitumen Spreader Functions

Re-Suction (This function allows the material to be returned to the tank again at the end of the series). Intermediate pump (This function allows the transfer of the material from one source to another without mixing with the material in the tank using the Distributor)

Asphalt Distributor Transport

VAD Series Asphalt Distributors are designed according to the request of our customers to be suitable for their own countries’ new or second-hand trucks. So, the high truck import expenses will be reduced. VAD Series can be put pre-montaged in to a 40ft container thanks to this design transportation costs are reduced significantly and it took only 5-7 days for the installation and training.