Total 1.3 m3 capacity spreaders can reach up to 5.40 meters width. Both Spreading Hoppers can be moved simultane ously or seperately.

Both Hoppers have 9 separate gates which can be controlled by PLC system or manual.

VCS5400 Chip Spreader by Vimpo, your reliable partner for precise chip spreading in road construction and maintenance. Engineered for efficiency and durability, this machine ensures uniform distribution of chippings on road surfaces, enhancing the longevity and quality of your projects. User-friendly and designed for professional operation, the VCS5400 Chip Spreader simplifies the process, making it the ideal choice for a variety of applications, from road construction to civil engineering. Elevate your projects with this top-tier chip spreader, ensuring safe and high-quality results on every job.

Turkey's first Chip Spreader VCS 5400, has been delivered to market. Vimpo introduce VCS5400 to General Directorate of Public Roads in 2014, VCS5400 offers a range of features and benefits, also provides solutions for many problems.

VCS5400 is designed and manufactured for heavy duty road surface coating works. With user-friendly and simple interface PLC controls have been designed for ultimate solution. All spreading and drive controls centralised on a single joystick control and steering by hydraulic steering wheel.

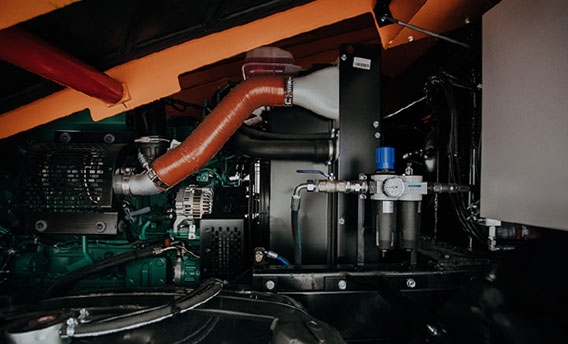

Variable width twin section spreading hoppers which is continuoslt expandable and with individual gates. the chpper is capable of spread widths of 300mm up tu 5.4 meters. The power unit and drive train have been designed to enable high speed travel capability between jobs to minimise downtime and maximise productivity. Simple operator controls minimise the time needed for operator training. Powerful 320 Hp engine allows the machine work in every condition.

| Engine | 320hp Volvo Penta Engine |

|---|---|

| Drive System | 4 Wheel Hydrostatic Drive System |

| Spreading Width | 5400mm Telescopic Expandable Spreadıng Width |

| Spreading System | Proportional Spreading System |

| Spreading Speed | 8 Km/H Spreading Speed |

| Cooling Systems | Heavy Duty Cooling Systems |

| Design | Deavy Duty Design |

| Cabin | Comfortable Air Conditioned Cabin |

| Camera | Rear And Front View Camera |

| Engine | 7,7 Liter 6 Cyl. 320 Hp/235 kW |

|---|---|

| Hyd. Tank | 360 Liter Hydraulic Tank |

| Belts | Two 500mm W. Belt Conveyors |

| Spread Hopper | 18 Ind. Pneu Gates For Each Side |

| Receiv. Hopper | Hydraulic Control |

| Spread Width | 5400mm Spread Width |

| Control | Auto Aggregat/m2 Spreading |

| Drive | Hydrostatic Drive System AWD |

| Brake | Hydrostatic Brake, Axle Brake |

| Operator | Colored PLC Touch Screen |

| Direction | Joystick Forward-Reverse |

| Cabin | Air Cond. A Refrigerator |

PLC Control - 300 - 5400 Spreading - Hydrostatic Drive - Velocity Dependent Auto Spreading - All Around Visibility - Cruise Control

Total 1.3 m3 capacity spreaders can reach up to 5.40 meters width. Both Spreading Hoppers can be moved simultane ously or seperately.

Both Hoppers have 9 separate gates which can be controlled by PLC system or manual.

Two 500mm wide belt conveyors. Feeding rate can be controlled by PLC automatically or manually by operator. Belt controls are linked to spreading hopper sensors to avoid overload.

Hydraulic controlled wings of the receiving hopper provides ease of operation and transfer of the Chip Spreader. Capacity of the receiving hopper is 2.5 m3.

Used tor towing dump truck whilst loading the hopper whith Hydraulic operation. Raise and lower lock and unlock can be controlled from the cabin for safa and secure hitching.

Angle of freedom provides easier turnings.

7,7 liter 6 cylinder, turbocharged, intercooler and water cooled 320 HP / 235 kW, 2200 rpm Heavy duty air filtration system 220 liter diesel tank.

Chip spreading controls are centralised on a daylight readable colour display and joystick controller to simplify peration. Road speed and roller speed automatically matched Manual adjustment permitted for fine tuning the spread rate Manual or automatic control of feed conveyors.

All spreading and drive controls centralised on a single joystick control and steering by hydraulic steering wheel. Cabin and drive functions are located to easy acces. Tow hitch movements can be controlled. Tow hitch interlock mechanism can be controlled. Cruise control Start and stop control for spreading. Forward and reverse motion.

Chip Spreader is controlled by a centrally controlled pneumatic system from the cabin and rear platform, and centrally controlled from the front cabin. When the material is finished, an audible and light alarm is given in the front cabin. It is used on cold paved roads, by being mounted on a truck tipper to lay gravel (aggregate) on the bitumen laid ground.

VCS 5400 Chip Spreader, pneumatic system controlled from the cabin with the Command Control System, applies equal crushing stone to all surfaces with the help of manual flow control. In the crushing stone pouring mechanism, the power transmitted pneumatically, operates the aggregate flow and dust holding hopper as a pin mechanism with the help of pneumatic pistons.

VCS 5400 Chip Spreader has a total capacity of 1.3 m3 and a spreading hopper with a width of 5400 mm. The spreading hopper can be expanded separately or at the same time. Each hopper has 9 laying covers that can operate separately. The width of the driver's cabin can be adjusted digitally. The feeding speed can be adjusted automatically or manually.

When the front hopper is full, there are sensors that measure the gravel level and automatically stop the conveyor. Hydraulically controlled blades provide convenience during transfer and operation. The capacity of the receiving hopper is 2,5m3. The tow hook is used to tow the vehicle while paving. There is a manual opening and automatic locking system for height and low adjustment, and a rotating mechanism system that prevents breakage when cornering.

Before using the VCS 5400 Chip Spreader, the oil ratio of the grease nipples in the gravel spreading mechanism should be checked. Make sure that the air distributor (conditioner) valve is open to the pneumatic system. All operator panel sockets should be checked.

VCS 5400 Chip Spreader has a pre-set control selection to enable the necessary parameters to work with joystick control. The paving amount is adjusted automatically according to the road speed. Vehicle speed and acceleration amount can be adjusted while laying or driving. Vehicle speed stabilization feature is available with one button.

The material to be poured is taken into the truck reservoir by adjusting the cover gap before the gravel is laid. After the power is turned on, the laying covers are opened. The gravel spreader connected to the tipper is moved by pressing the "run group" button in the cabin. At the end of the work, it is turned off by pressing the "group run" button. The daily maintenance of the vehicle is done by turning the power off.

Before starting the maintenance, the machine should be cleaned. After the engine is turned off, the ignition key is taken and the handbrake is applied, the maintenance and repair process can be started. After the maintenance works and inspection, all the safety parts (locking washer and pin, screws, bolts and nuts) that need to be changed should be replaced. If welding is required on the paver or its chassis, it should be performed by an experienced welder. Using the equipment incorrectly or by untrained personnel can be dangerous. Learn the correct use and location of all controls.

Regular maintenance should be performed on the unit to avoid unnecessary damage and repair and to ensure maximum operation and performance. Bearings, seals and bushings mechanical fittings should be checked and oil in the grease nipples should be checked with an accelerated maintenance program after a certain operating period (100 hours of initial operation).

To operate the VCS5400 Chip Spreader, the machine main switch is turned on. The ignition is turned to the right and the vehicle is started. Vehicle engine speed runs at 740 Rpm. The Entry Screen is the screen image that appears after the VCS5400 Chip Spreader contact is activated.

When the screen comes on, the parking brake is activated automatically. The vehicle runs at idle 740 rpm. The joystick and other commands do not work on this screen. The Laying Screen is the screen image that comes after pressing the spread button after the entry screen. The laying screen led lights up. The vehicle runs at 1850 rpm at high speed. The joystick and other commands are active on this screen.

Gravel Size Selection Box is used to select the type of gravel to be paved. To change the size of the gravel, the selection button is turned, the box is selected and the outer frame of the box becomes green. To change the Gravel Type, the Selection Button is pressed once and the outer frame of the box becomes red. Gravel size is selected by turning the Selection Button and confirmed by pressing once.

Speed Selection Box is used to set the speed of the chip spreader as a percentage while preparing for or during laying. To change the speed of the VCS 5400 Chip Spreader, respectively, the selection button is turned to select the box and the outer frame of the box turns green. Press the Selection Button once to change the value and the outer frame of the box turns red. By turning the Selection Button, the percentage of the speed is selected and confirmed by pressing the button once. You can see the speed of the gravel paver from the speedometer dial and digital display (km/h, m/d) in paving or driving mode.

To use the VCS 5400 Joystick, firstly the safety catch is kept pressed. The lever arm is brought to the neutral position to go forward, to the back to go backward and to the neutral position to stop. The stop button is used to stop the gravel spreader. While the screenshot is in input mode, the engine speed will run at 740 rpm idle speed. To stop, the button must be pressed and the main switch of the machine must be turned off.

Adding equipment to a vehicle will change the handling and performance characteristics of the carrier vehicle. These changes include steering wheel operation and travel speed, center of gravity, fuel consumption, and vehicle wear and tear.

Sharp turns should not be made. Vehicle speed should not exceed 6-10 km/h during crushing. Compliance with the environmental conditions during applications and operation is the responsibility of the operator. The speed of the vehicle should not exceed 25km/h while filling the gravel hopper and during the gravel laying process.

It should be ensured that the machine is secured and parked safely before ending the working position. Engine exhaust fumes and aggregate dust should not be inhaled.

During loading and towing by the vehicle, it should not be entered between the crusher and the vehicle. The lifting apparatus should be replaced with a new one when it undergoes physical deformation. In specified weight (tonnage) should not be exceeded. During loading, the vehicle should not be approached more than 25 meters.

Transport must be on the vehicle, loading and unloading must be done with a crane, the connection must be arranged so that it is kept in horizontal position by three lifting ears on the chassis. It should not come closer than 10 meters to the gravel mechanism.

The distances of the covers should be adjusted manually with the help of rods (studs) according to the amount of gravel to be laid on the ground. It should be checked whether the reflectors are working or not. The operator who will use the machine, dust etc. must use masks and goggles in order to be protected from external factors.

We have all road construction machines. Find the product you need.

ALL PRODUCTSVimpo Machine Pvt. Ltd. (Factory)

Plot No. PAP-160, Village - Shinde, TAL-Khed.Dist- Pune, Chakan phase-2 Maharashtra-410501

+91 6359-818748

Venta-Tech LLC

sale@venta-tech.com

+380671229797 Whatsapp/Telegram

АСТРА

Krasnoshkolnaya Embankment 2, Office 22, 61050 Kharkiv

+380577329505

TREMCO Transport Equipments Manufacturing Company

Sabhan, Block 11, Building 224 Sabhan, Block 9, Building 100

+965 9720 6090

EAST EG ENGINEERING AND SERVICES TECHNOLOGY SAE

30 ST 276 New Maadi, Cairo 11742, Egypt.

Tel: +20 2 2519 3383 |Ext 139 Fax: +20 2 2519 3381

In this section, you can find our blog content where we bring together innovations in road machinery and bitumen processing technologies, industry developments, and VIMPO’s expert perspective. In this space where we aim to share information and content that adds value to our customers, we are here with updates on our products, projects, maintenance tips, and the latest industry news. With content based on our expertise, you can closely follow the latest developments in road construction and bitumen applications.

What Is Asphalt Asphalt is a mixture of, aggregate, binder and filler. Aggregates used for asphalt mixtures can be crushed rock, sand, gravel or slag. A binder is used to bind the aggregates in a sticky mixture. Commonly, bitumen is used as a binder. Although asphalt is main

What is chip sealing? Chip sealing is a pavement surface treatment that involves the application of a liquid asphalt binder, followed by a layer of crushed stone or aggregate chips. This treatment is used to seal and protect the surface of the pavement from wear and damage c

Bitumen Emulsion Bitumen emulsion is a versatile and widely-used material in the construction industry. It is a mixture of bitumen, water, and an emulsifying agent, which allows it to be easily applied as a liquid to surfaces in a thin layer. Bitumen is a sticky, black, hydr